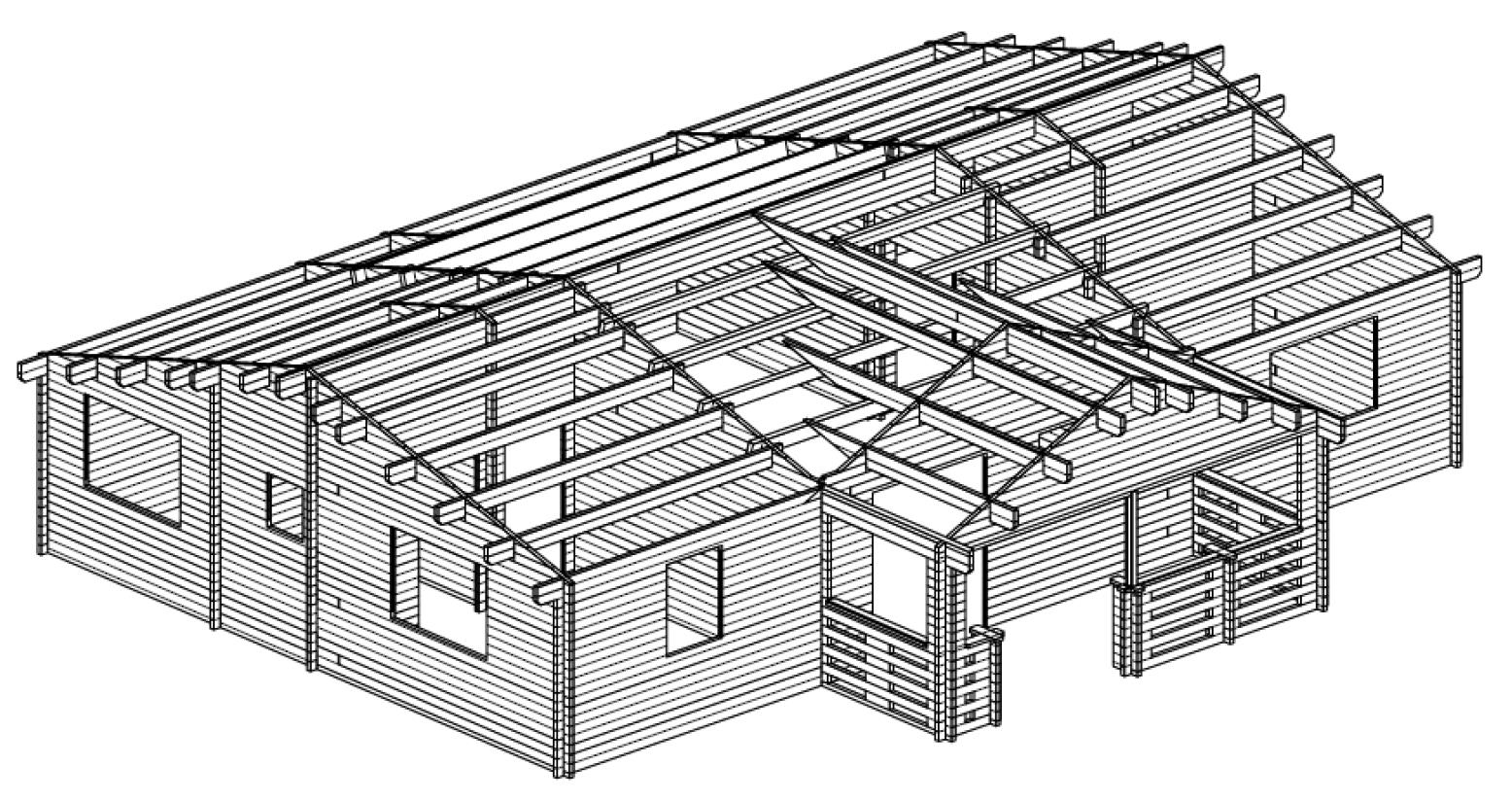

Larger cabins and homes for year round dwellings can be virtually any design. We manufacture to order, and to meet local building code requirements for wind and snow loads. For increasing wall heights, adding roof purlins or changing roof slopes the simplicity and versatility is unmatched.

This all natural construction is efficient, and has virtually no waste. Home packages are delivered to site with components pre-cut. Assembly is simpler that conventional construction, reducing labor costs. With the combined thermal mass of a solid wood wall and the insulation, the energy efficiency has unmatched value.

The use of a local engineer is required to adapt our construction methods prior to production to ensure the package meets local requirements.

Type of Wood

All material is a northern spruce grown in a cold climate, creating a tight grain and is the most accepted and stable material for log construction. The wall logs sizes and moisture content is consistent, allowing for accurate production and assembly. The wood has been kiln dried to 16% moisture content and can air dry to less than 14% prior to milling.

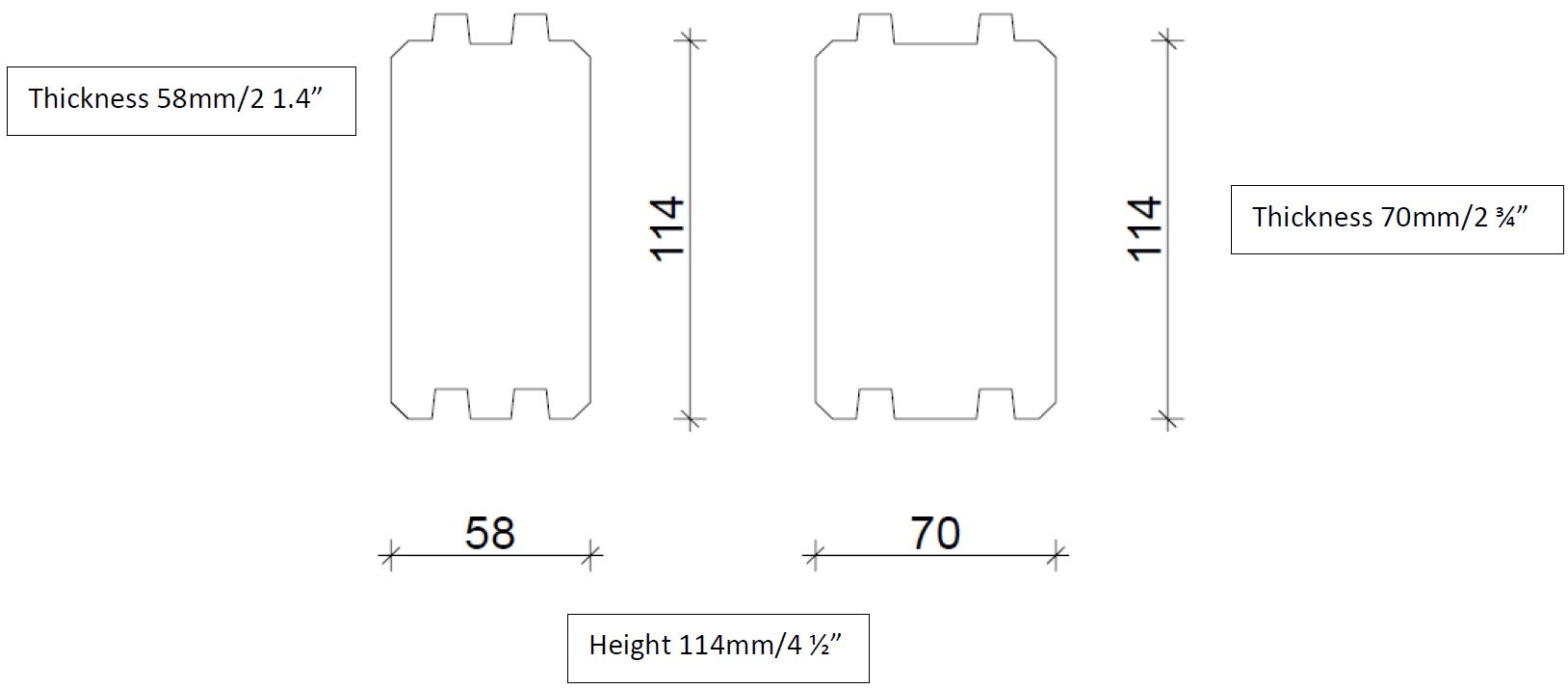

Wall Log Sizes

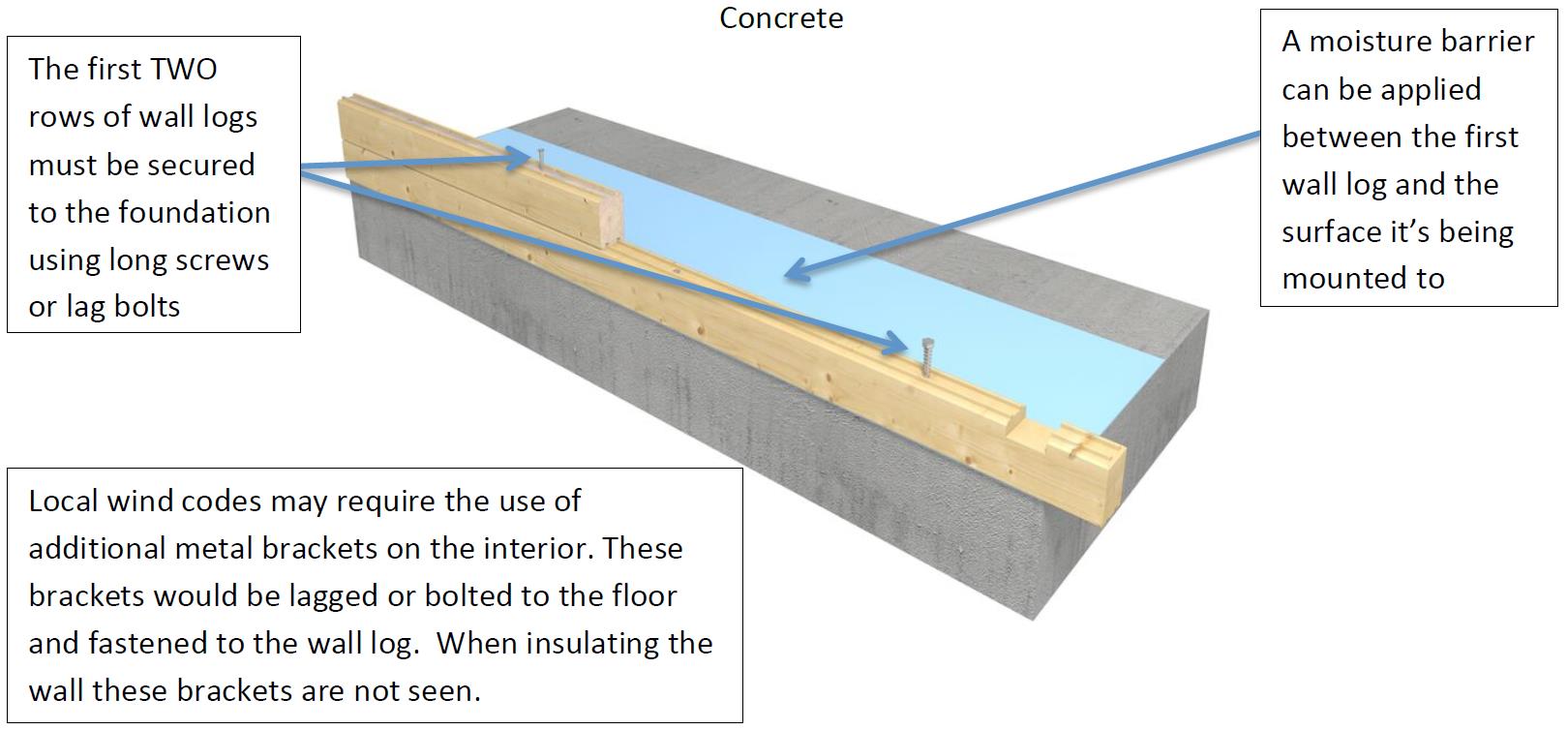

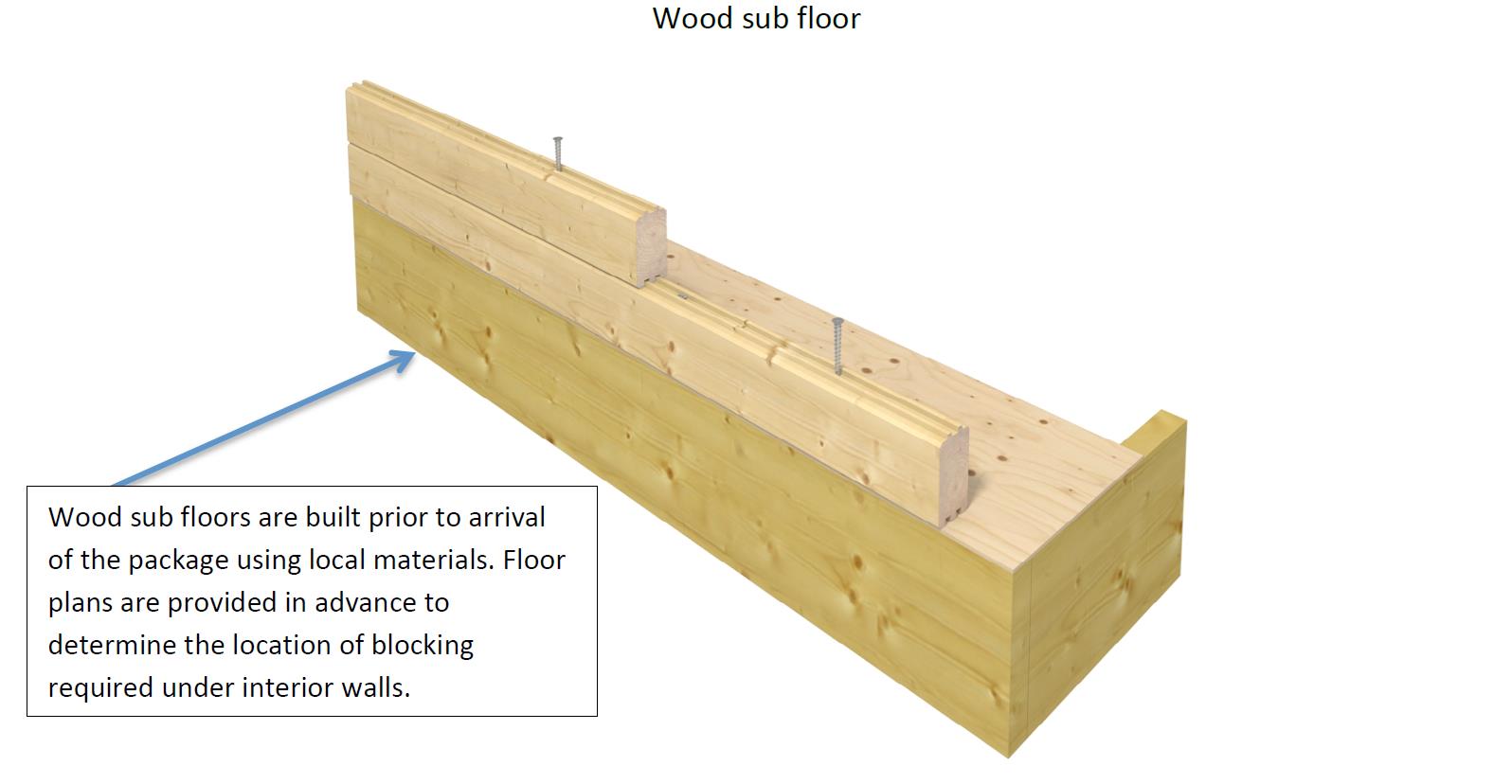

Mounting first two rows of wall logs to foundation

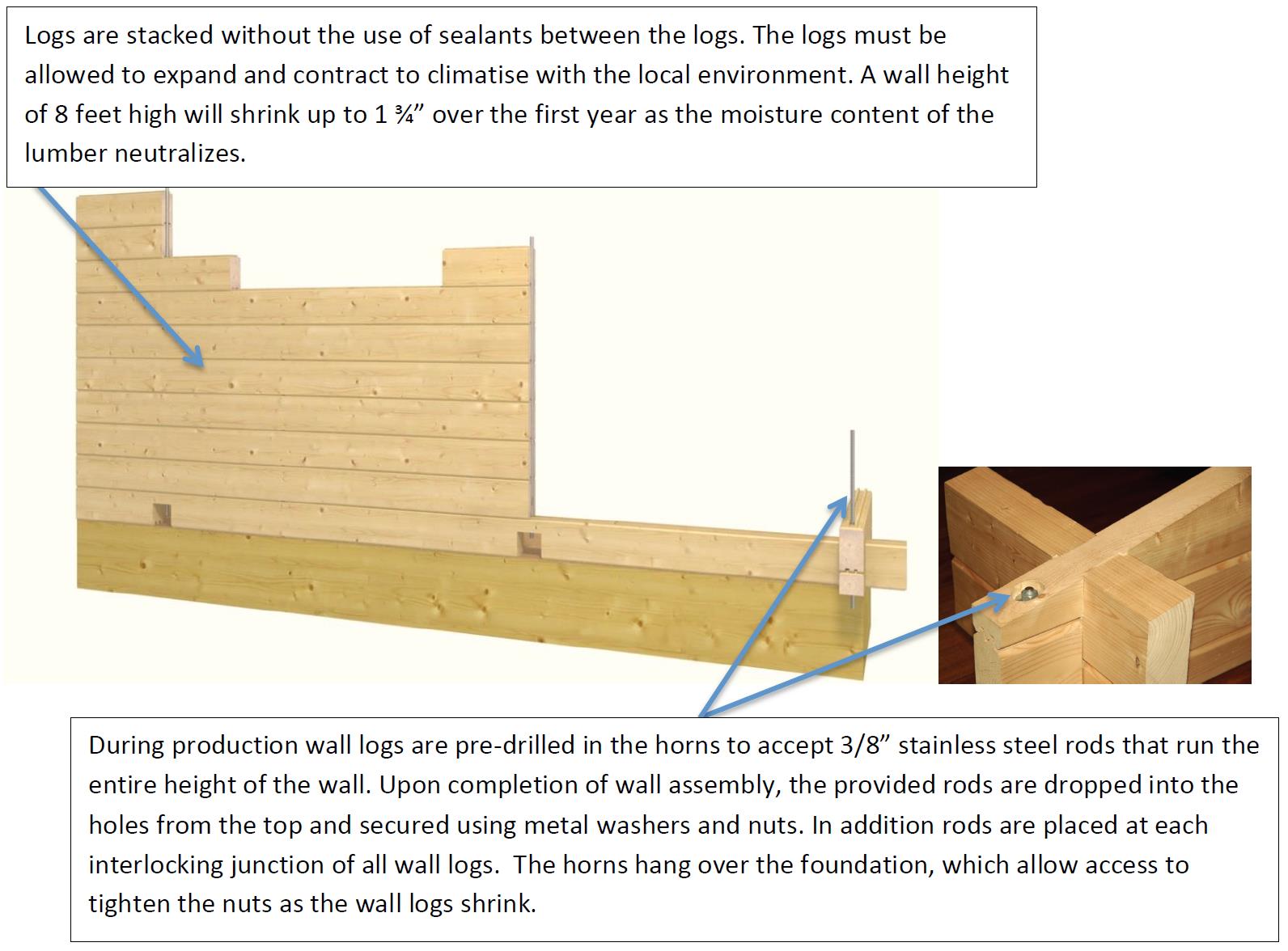

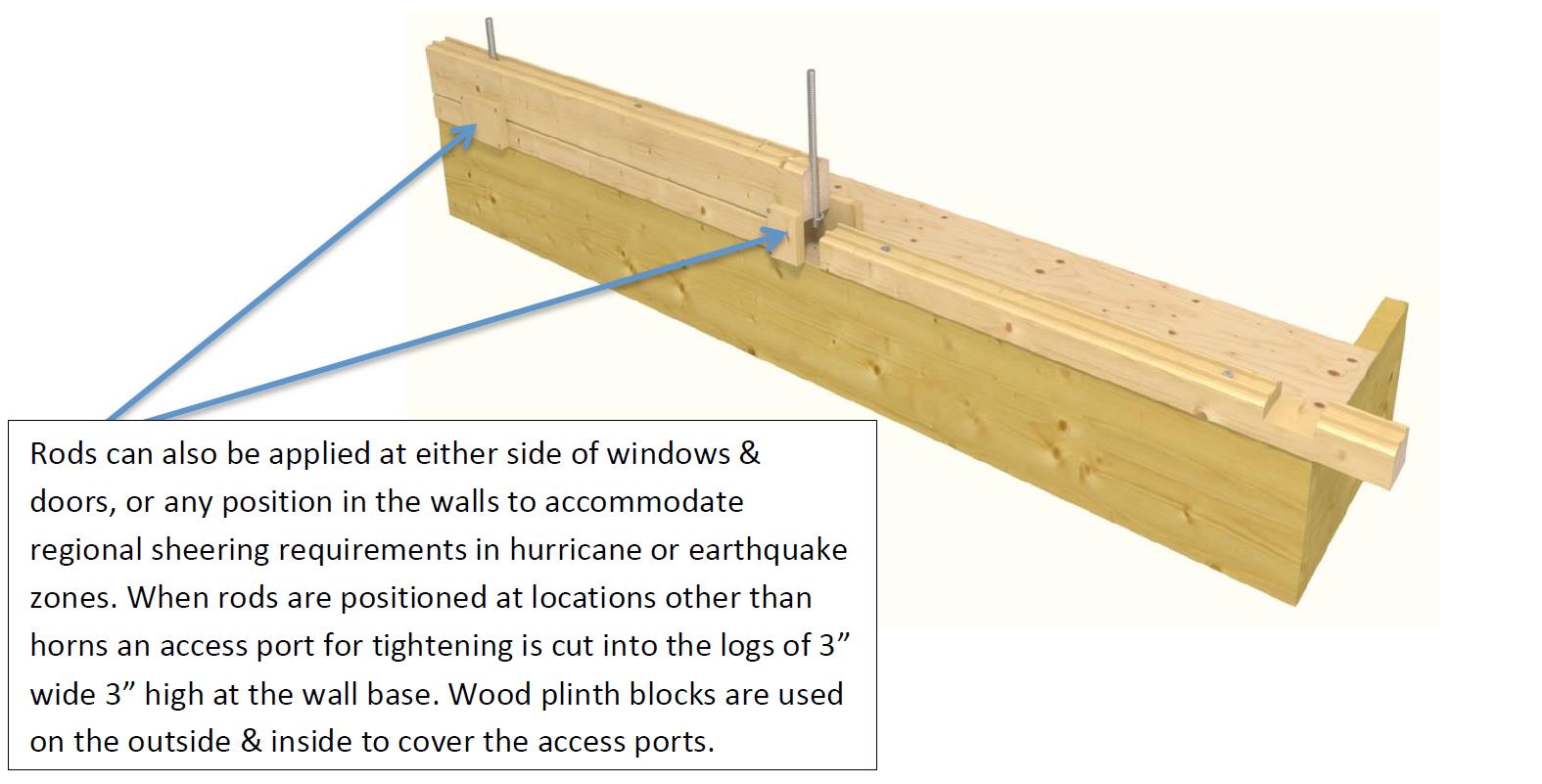

Stacking of wall logs

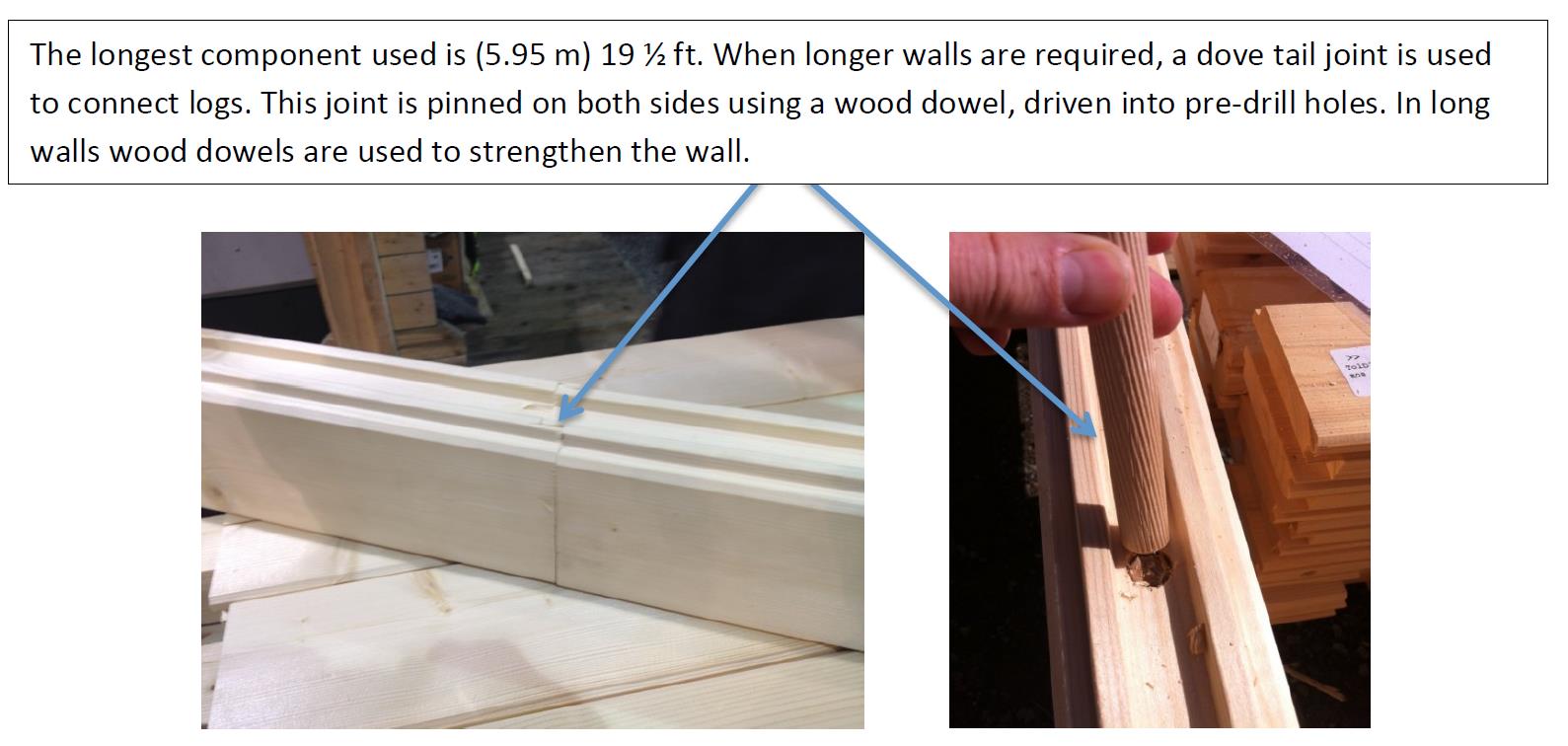

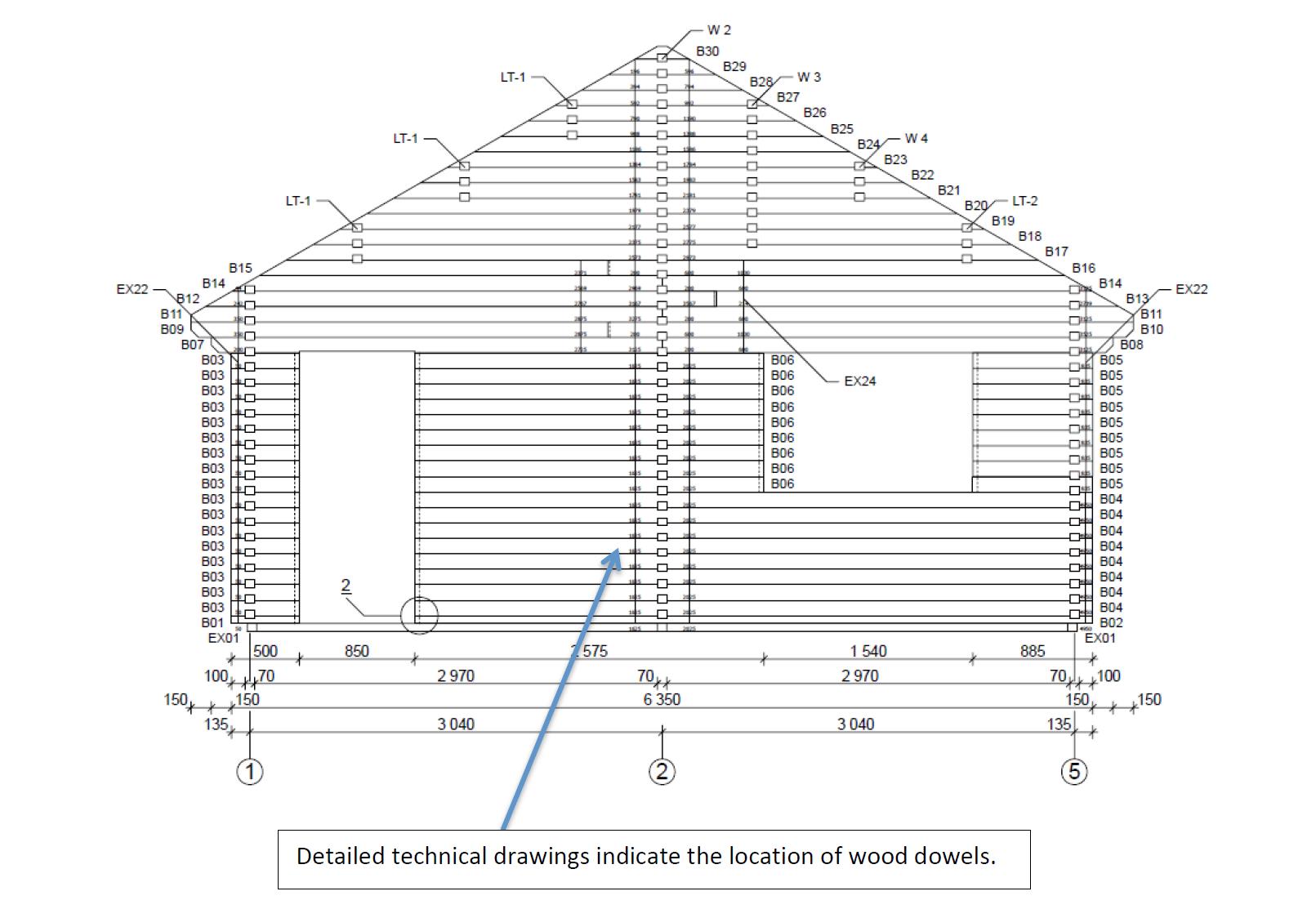

Length of wall logs

Gable Ends

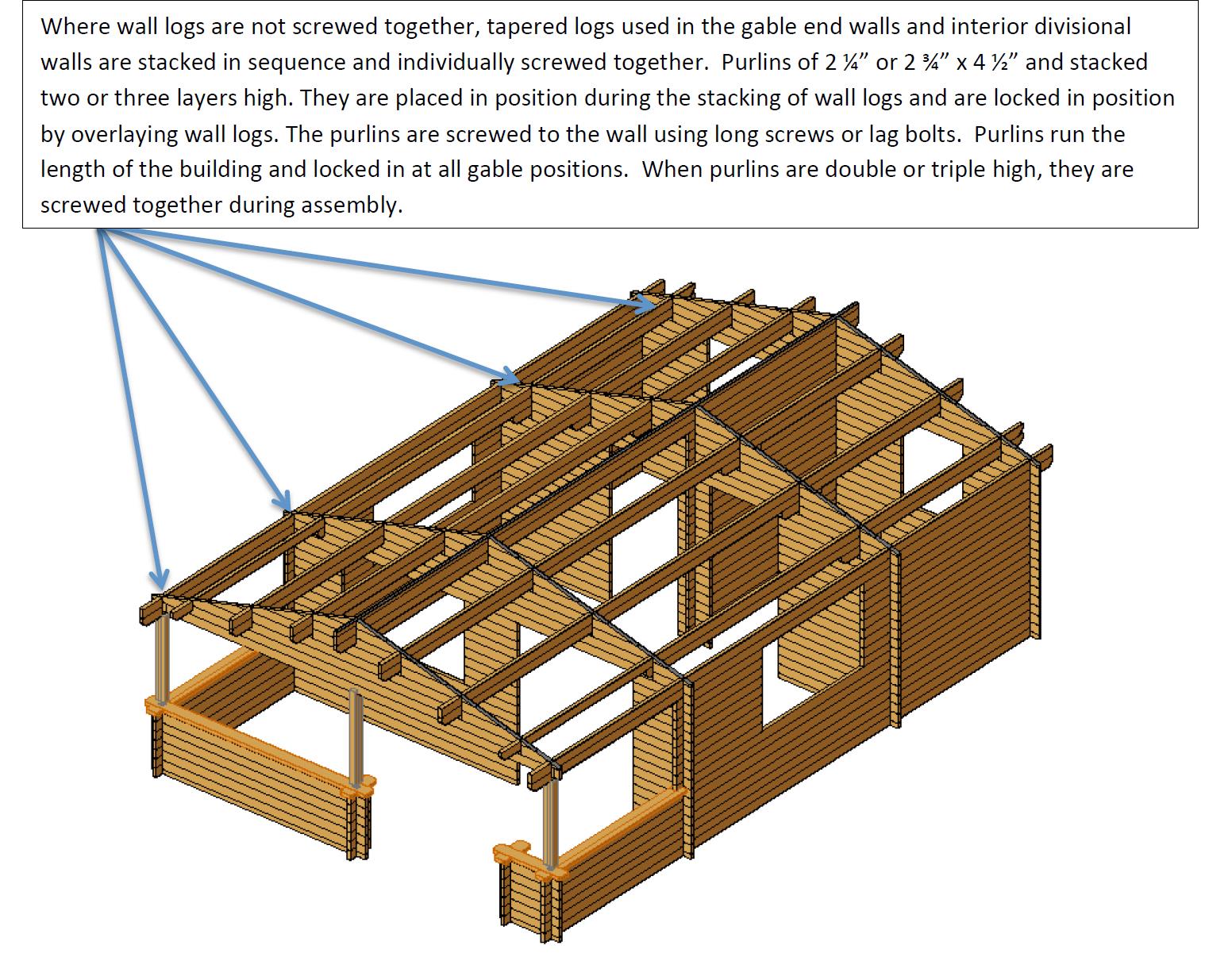

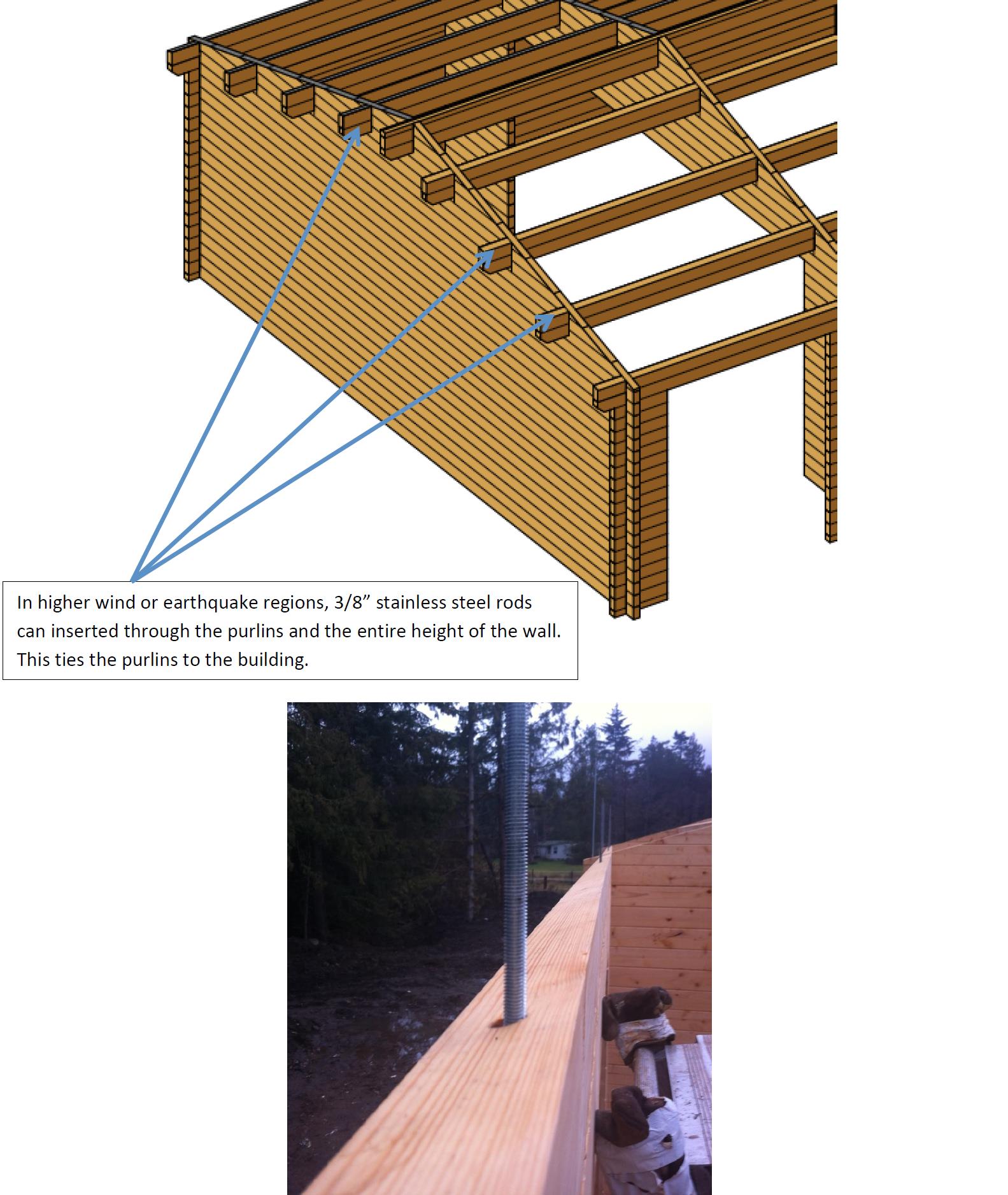

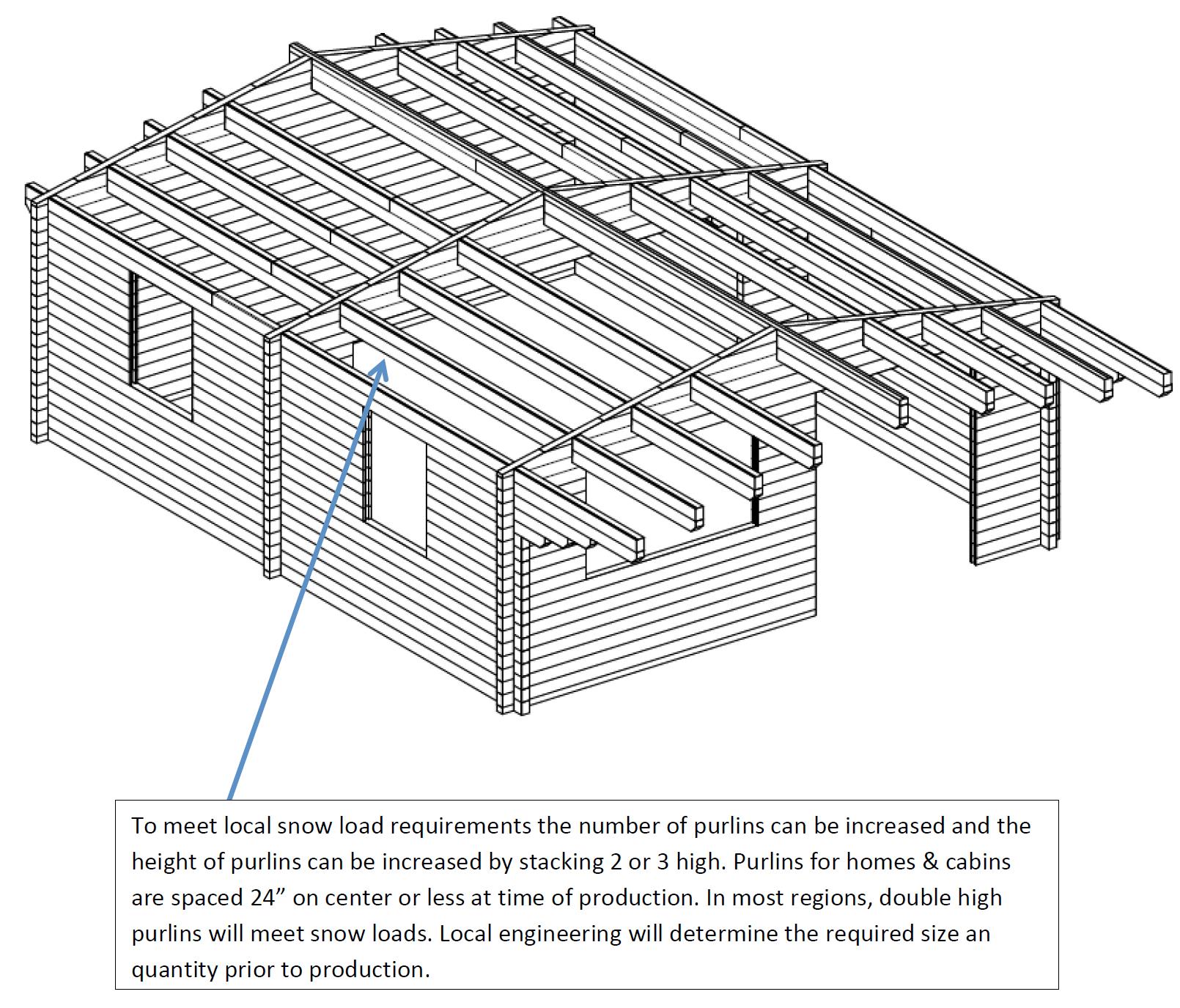

Roof Purlins & Snow Loads

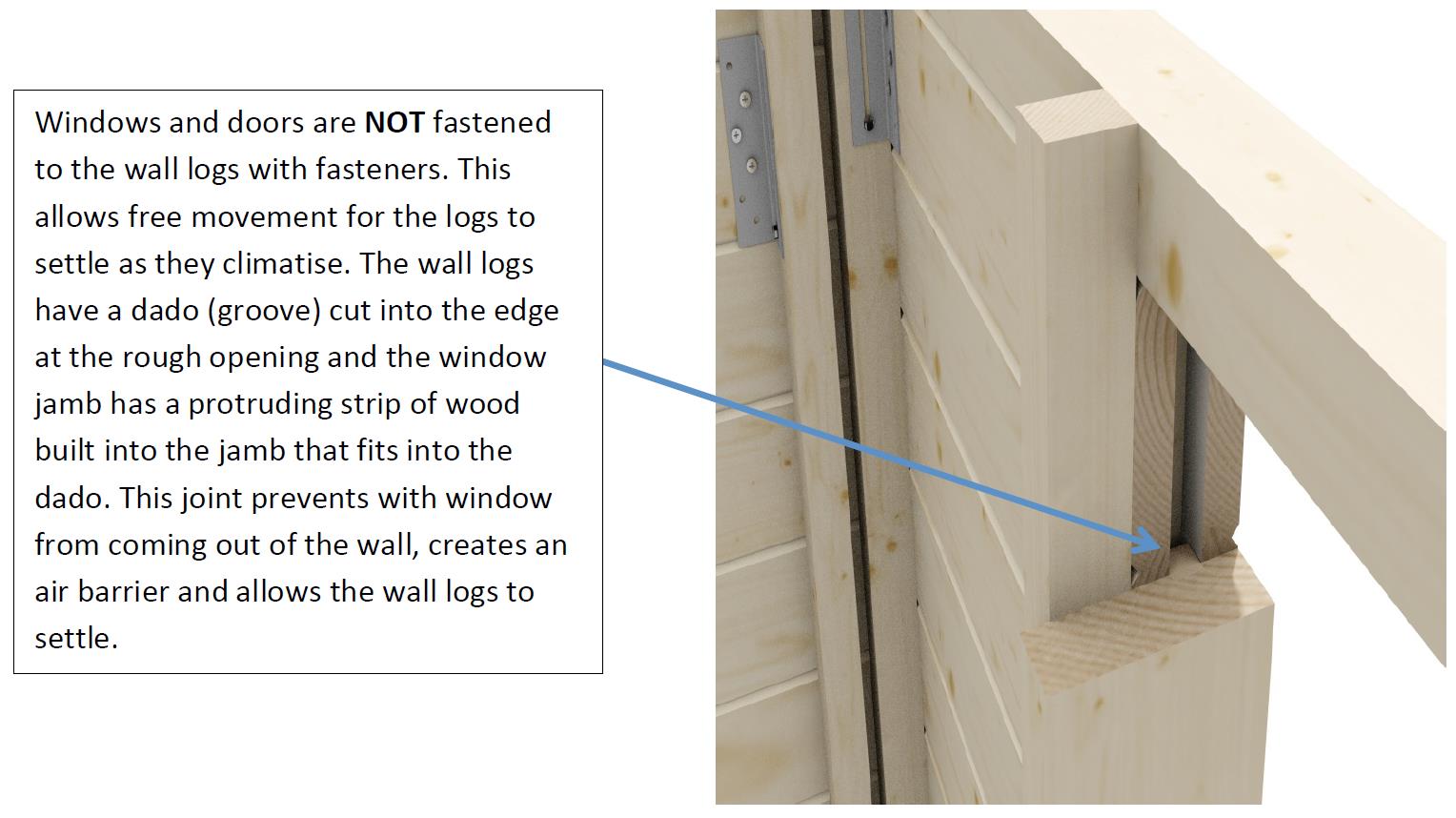

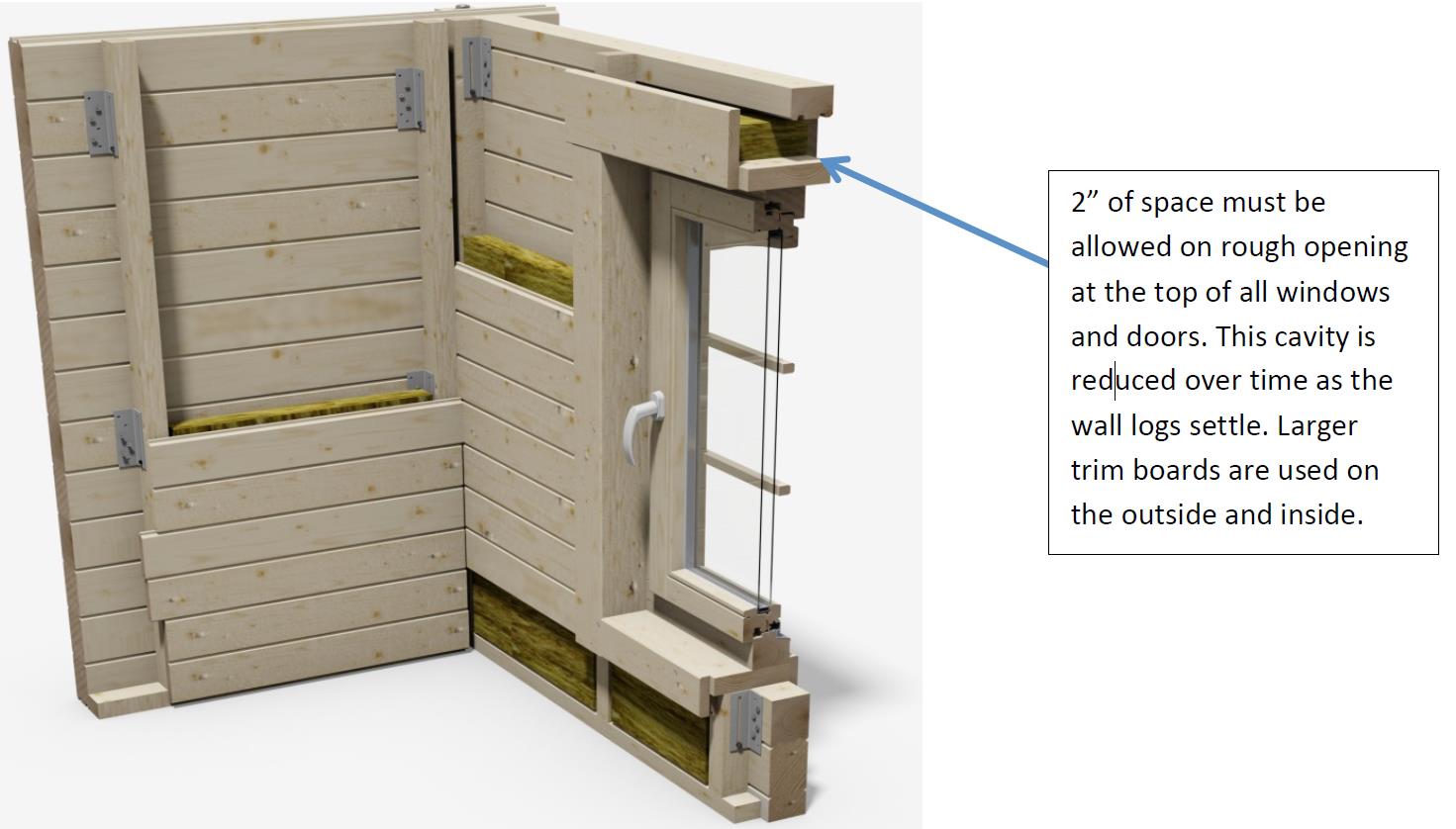

Windows & Doors

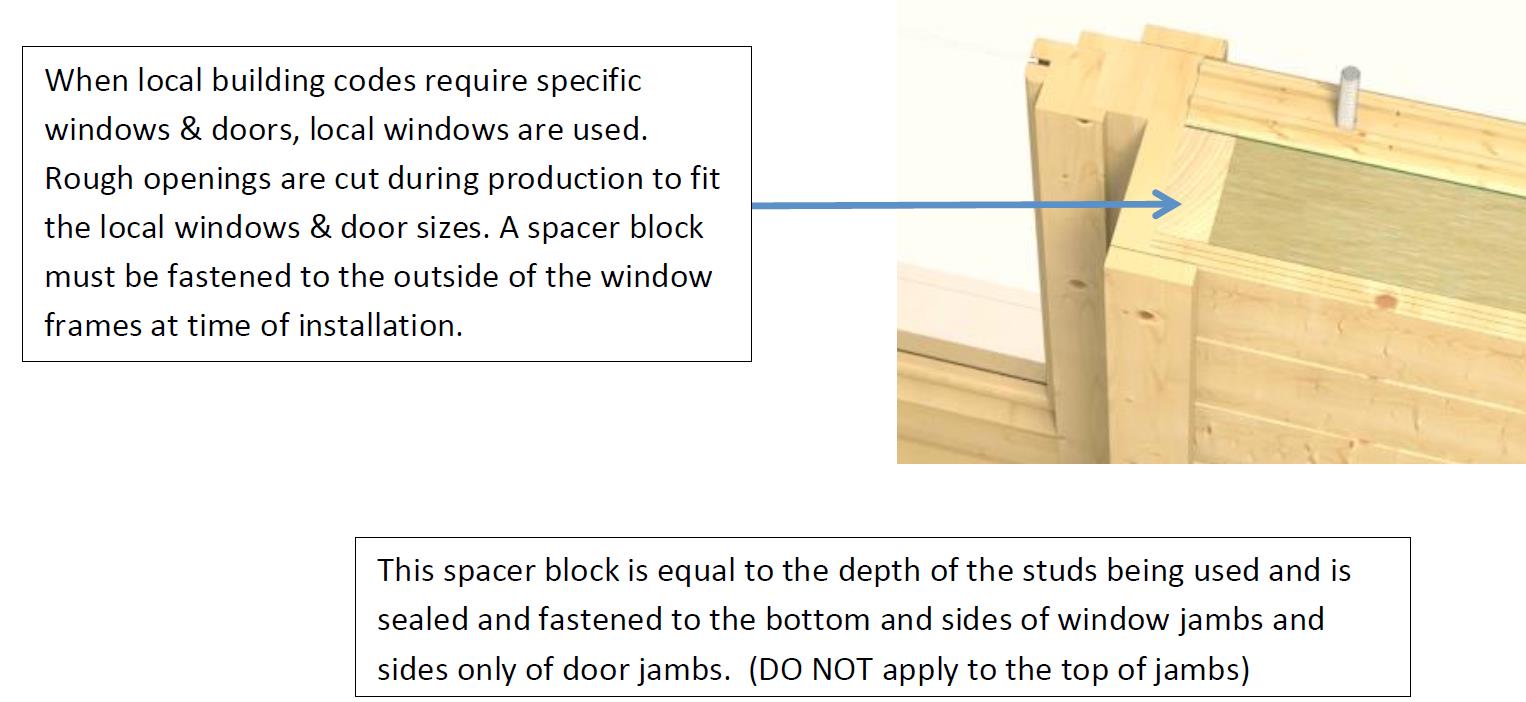

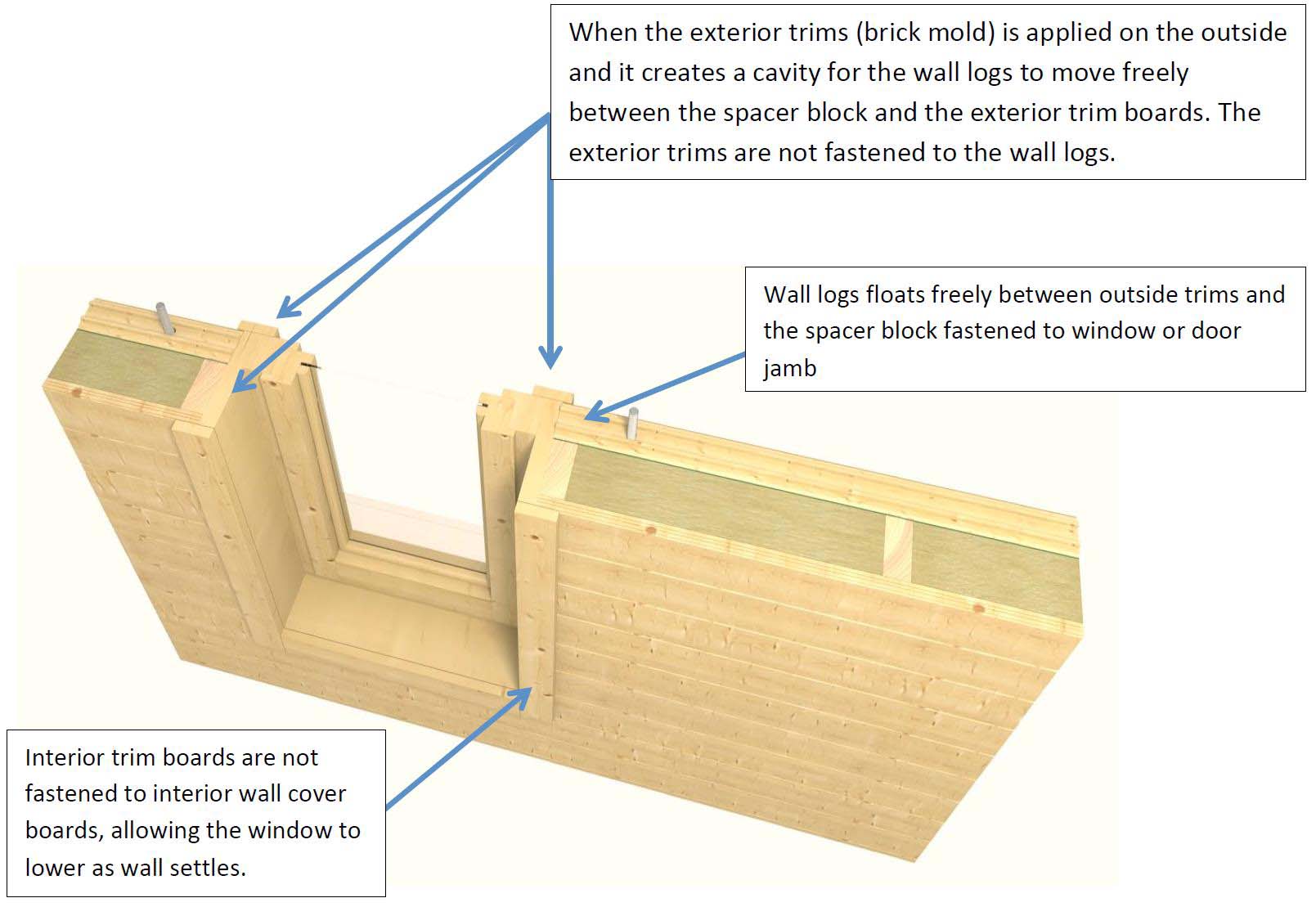

Using Local Windows

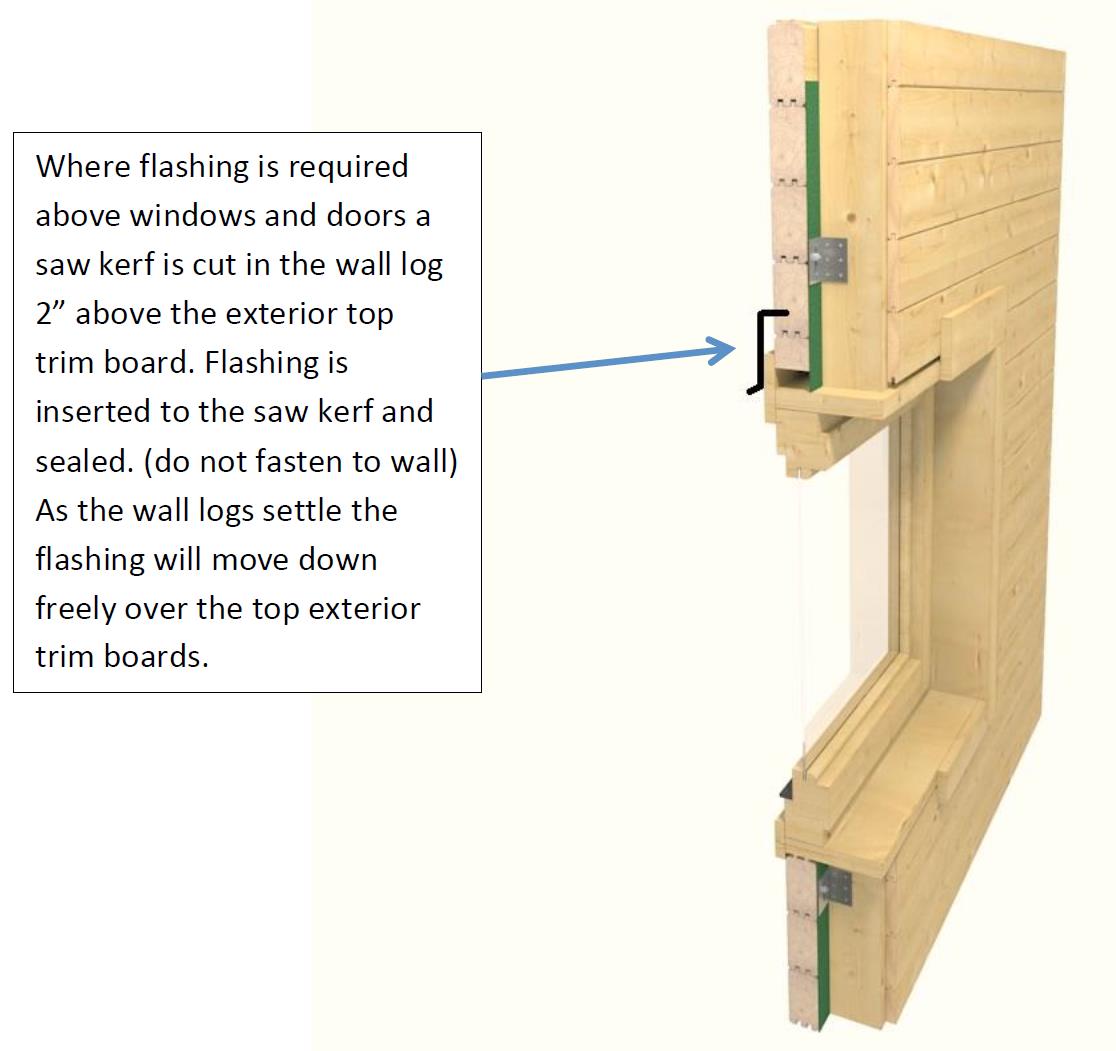

Flashing

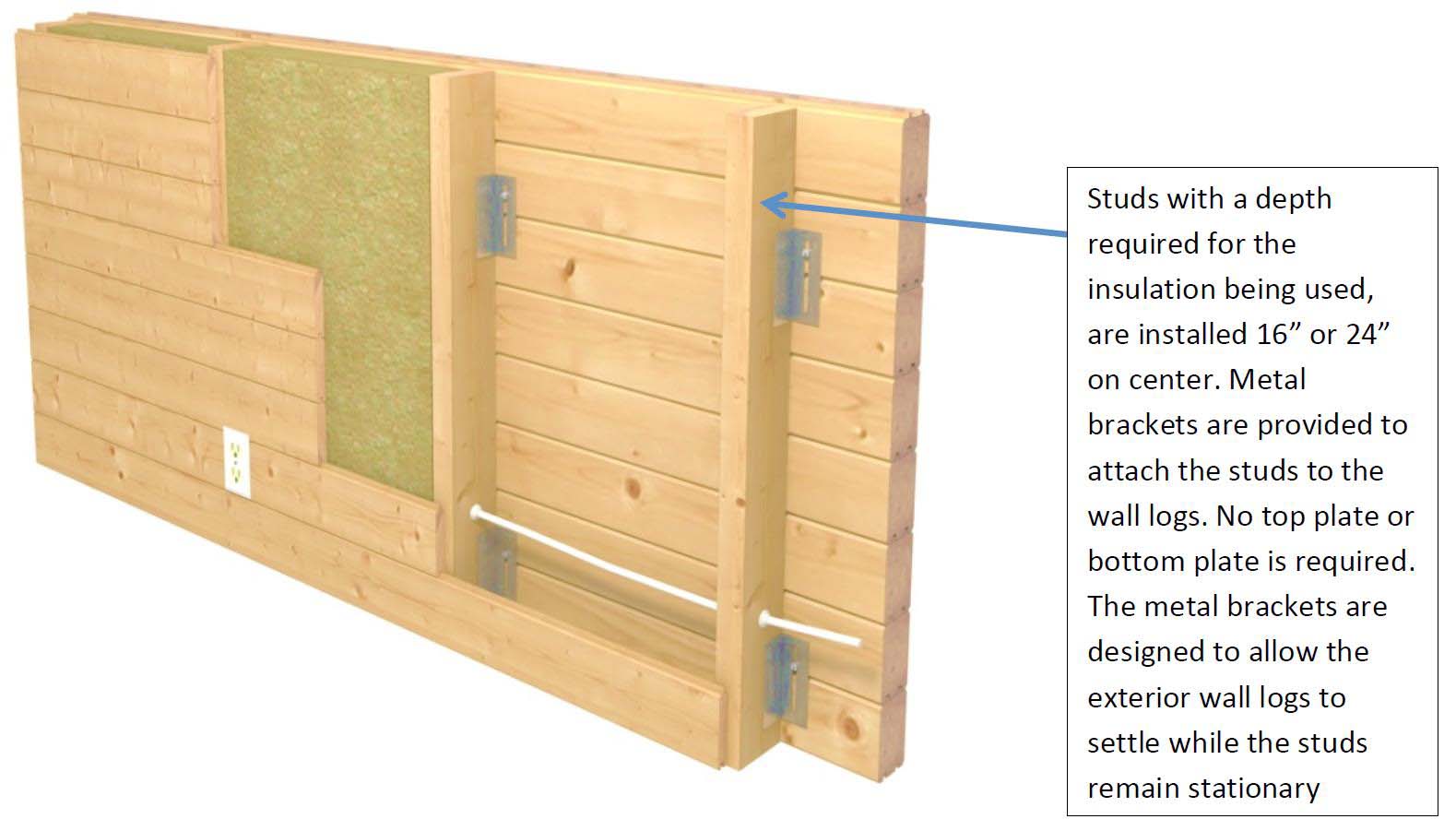

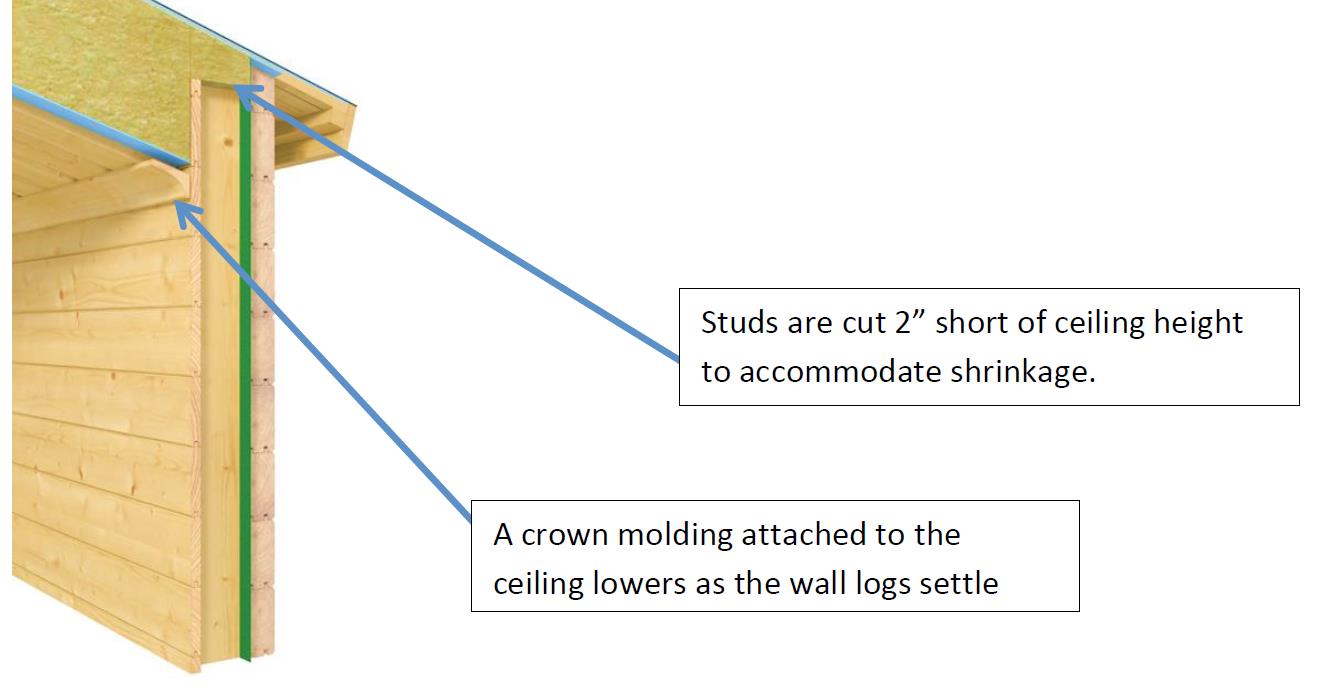

Insulating Walls

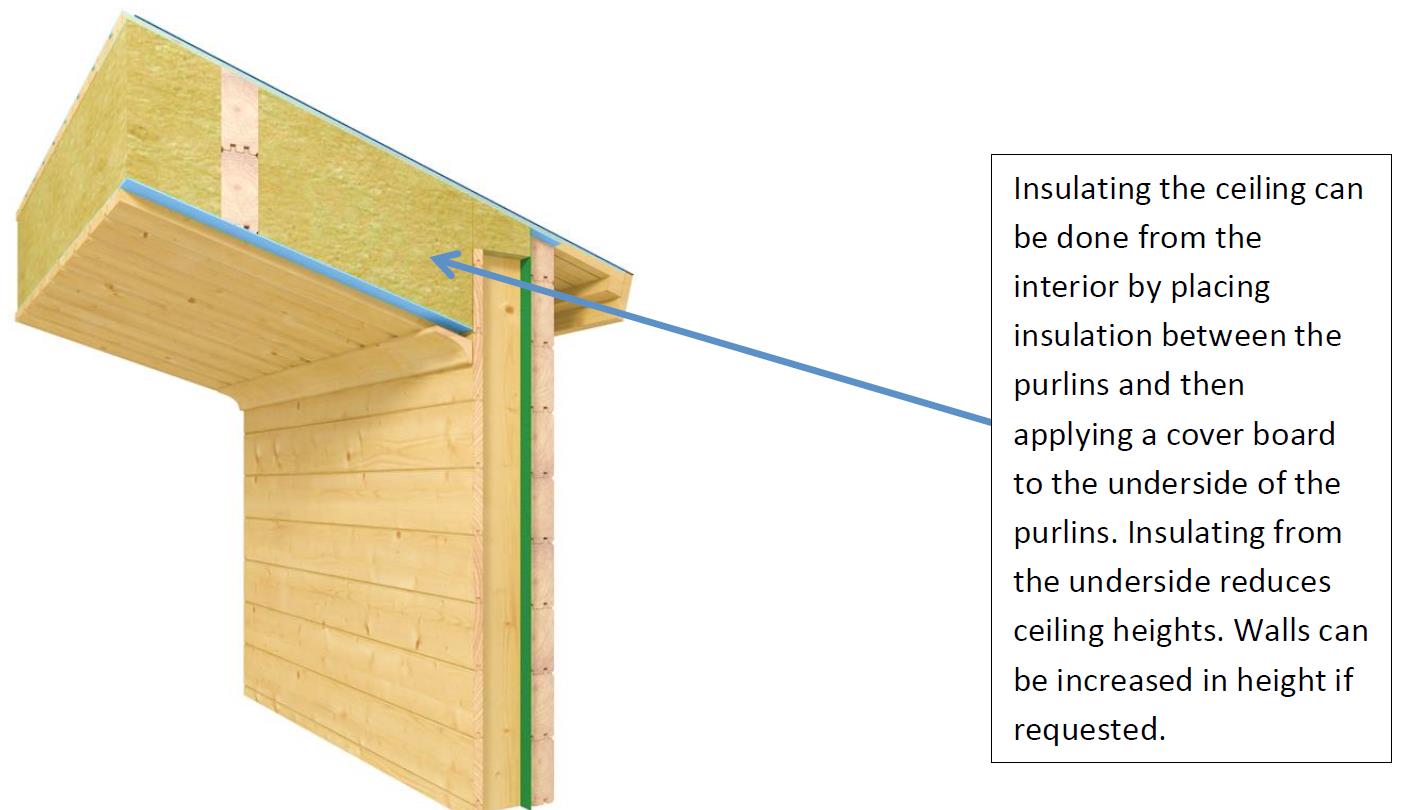

Insulating Ceilings - Option 1

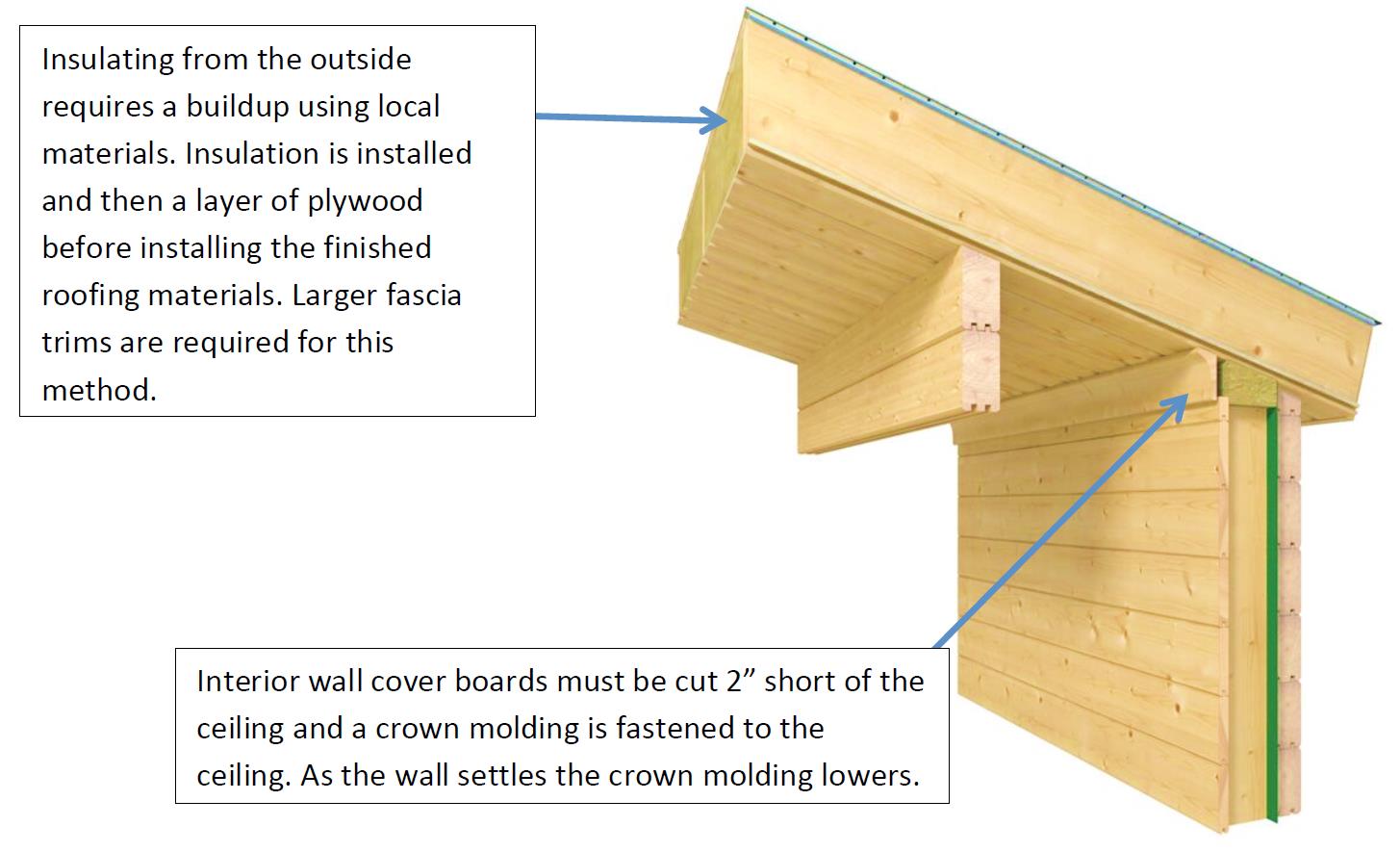

Insulating Ceilings - Option 2

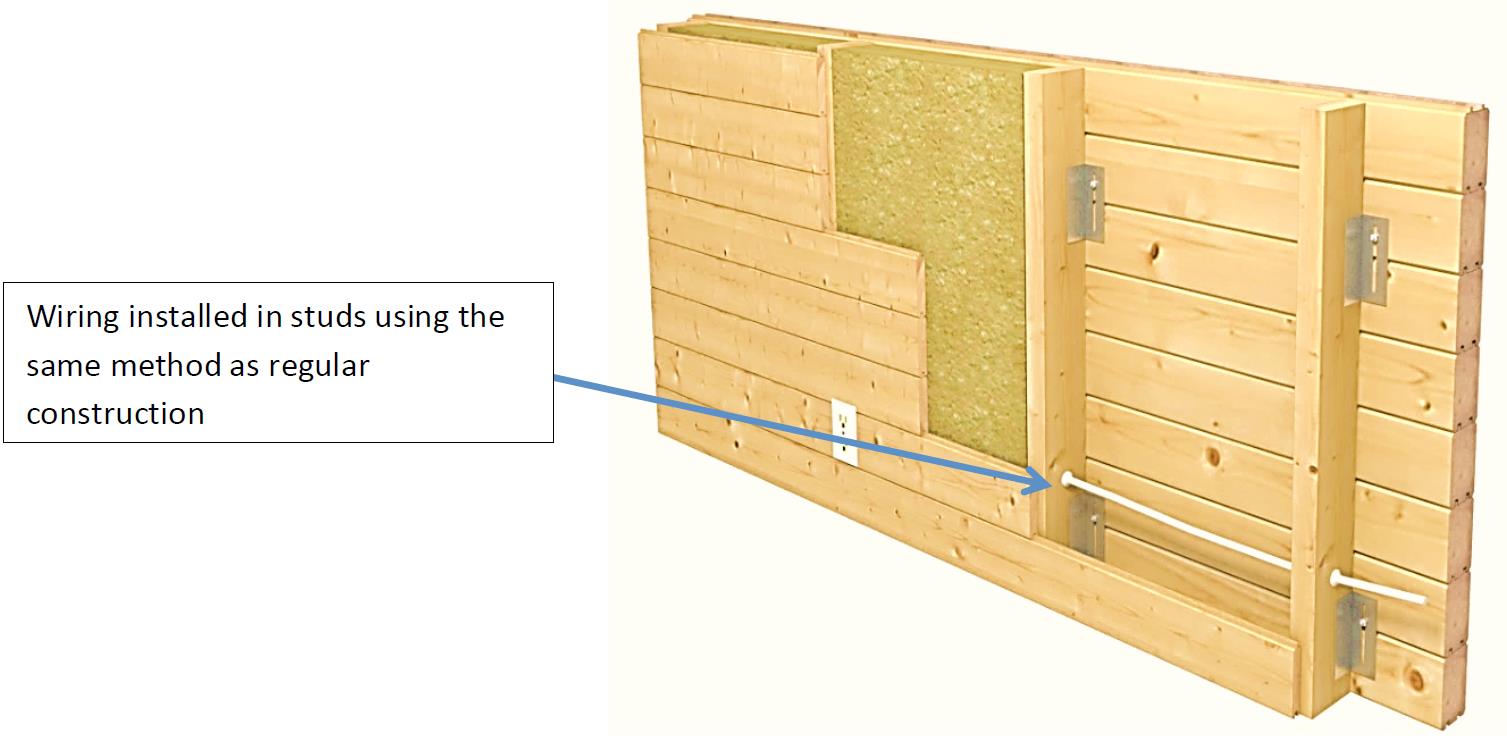

Electrical Wiring

Vapor Barrier & House Wraps

Must be determined by local engineers based on regions climate.

Wood Treatments

The wood must be sealed on the interior and exterior wall surfaces immediately following assembly. High quality treatments are available locally; similar to what is used on wood decks or fences. Research the wood treatments used in your region from approved manufacturers.

Maintenance

During the first year, storm rods need to be tightened as the moisture content reduces and the building settles. At the end of the first year tightening will not be required. Exterior and interior staining or painting will be required as recommended by the stain or paint manufacturers.